Additive Manufacturing (3D Printing)

3D Printing & Additive Manufacturing: A Pillar of Strategic National Capability

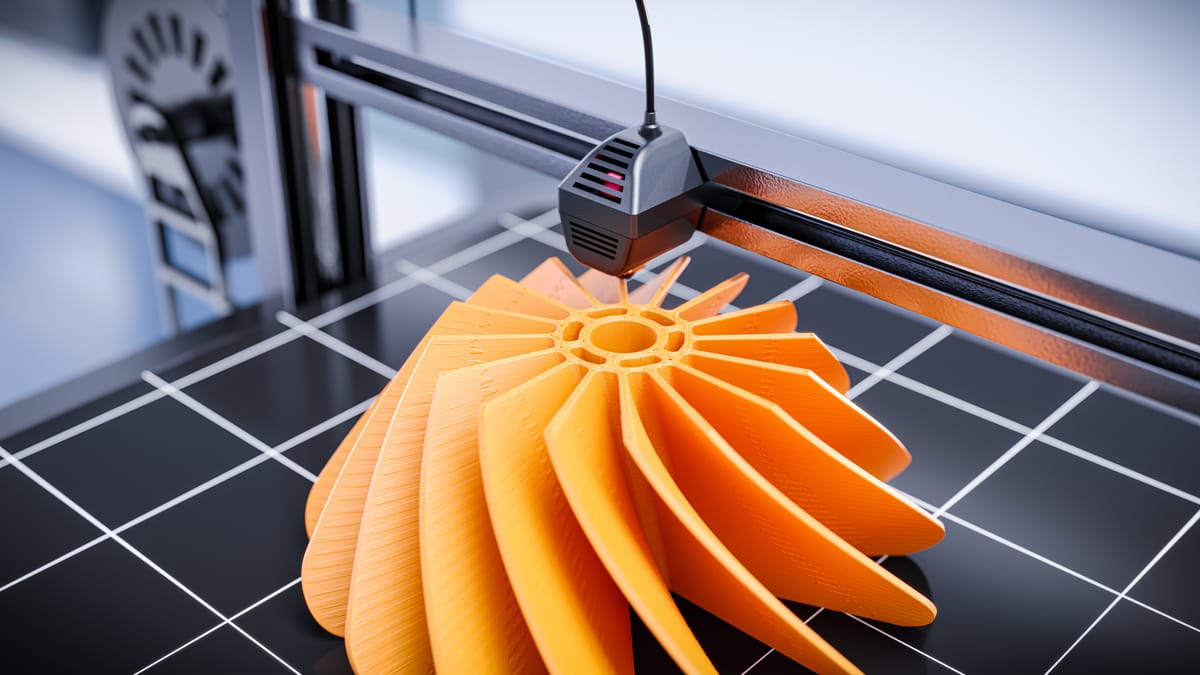

Additive manufacturing (AM), commonly known as 3D printing, enables layer-by-layer fabrication of complex parts directly from digital designs, transforming supply chains and industrial base resilience. By consolidating multiple components into monolithic structures, optimizing internal lattices for weight reduction, and tailoring material properties through gradient control, AM provides unmatched design freedom and rapid production agility. Nations that master a spectrum of AM processes and materials secure strategic advantages in defense, aerospace, medical devices, and critical infrastructure maintenance.

At its core, metal powder-bed fusion (PBF) techniques—such as selective laser melting (SLM) and electron beam melting (EBM)—use high-powered energy sources to selectively fuse metallic powders (titanium, aluminum, nickel-based superalloys) into fully dense components with mechanical properties on par with wrought alloys. Key process parameters—laser power, scan speed, hatch spacing and layer thickness—must be finely tuned to balance part density, microstructure control and residual stress minimization. Directed energy deposition (DED) systems complement PBF by feeding wire or powder into a melt pool on an existing substrate, enabling large-scale repair of damaged turbine blades and on-demand manufacturing of low-volume structural elements.

Polymer extrusion methods—such as fused filament fabrication (FFF) and pellet extrusion—serve rapid prototyping and tooling applications using engineering plastics like polyetheretherketone (PEEK) and reinforced composites with glass or carbon fibers. Binder jetting extends AM to ceramics and refractory metals by depositing liquid binders onto powder beds, creating green parts that undergo post-process sintering to achieve high temperature resistance in turbine and heat-exchanger components. Multi-jet fusion and vat photopolymerization unlock ultra-fine resolution for medical implants and dental prosthetics, where sub-100 µm feature sizes and biocompatible resins are critical.

Strategic Importance

From a national capability standpoint, additive manufacturing fortifies supply-chain resilience by enabling decentralized production of spare parts for aircraft, naval vessels and armored vehicles, reducing lead times from months to days. Complex geometries—such as conformal cooling channels in injection-molding dies or lattice-reinforced shock-absorbing structures—enhance performance while cutting material use by up to 60 percent. In humanitarian and disaster relief scenarios, portable AM units can fabricate medical tools, water-purification housings and shelter-assembly components near forward operating bases or remote communities.

Leading Nations in Additive Manufacturing

United States maintains leadership through government-industry consortia like America Makes, advancing high-rate PBF systems and qualification standards for critical aerospace and defense components. China rapidly scales production capacity with domestic machine tool manufacturers and state-backed AM centers, focusing on large Ti-alloy structures for high-speed rail and aviation. Germany excels in industrial-grade polymer AM and metal-DED repair technologies, with OEMs integrating in-line AM cells into automotive production lines. Japan drives innovation in precision resin-based AM and ceramic binder-jetting for semiconductor lithography components, while fostering national interoperability standards. India is expanding its AM ecosystem through public–private partnerships in aerospace maintenance, medical device fabrication and vocational training programs to build a skilled workforce.

Future Trajectory

Next-generation AM will integrate real-time process monitoring—using melt-pool sensors and layer-wise tomography—and closed-loop control powered by machine-learning algorithms to ensure defect-free builds. Hybrid manufacturing systems combining subtractive and additive steps will deliver near-net-shape parts with minimal finishing. Advances in multi-material printing and functionally graded materials will enable single-step fabrication of components combining wear-resistant surfaces, lightweight cores and embedded sensor networks. By investing in national AM standards, certification frameworks, and localized powder-production capabilities, nations will secure an agile manufacturing base that underpins both economic competitiveness and strategic autonomy.